UNDERSTANDING POROSITY FORMATION AND PREVENTION WHEN WELDING

Por um escritor misterioso

Last updated 21 fevereiro 2025

Keyhole laser welding is a joining technology characterised by the high focussed power density applied to the workpiece, facilitating deep penetration at high processing speeds. High aspect-ratio welds produced using this process invariably have narrow heat-affected-zones and minimal thermal distortion compared with traditional arc welding processes. Furthermore, the ability to process out of vacuum and the easy robotic manipulation of fibre optically delivered 1?m wavelength laser beams, allow keyhole laser welding to process geometrically complex components. The widespread uptake of keyhole laser welding for the production of titanium alloy components in the aerospace industry has been limited by the stringent weld quality requirements. Producing welds with levels of subsurface weld metal porosity content meeting the required weld quality criteria has been the primary obstacle. Here, three techniques for controlling the levels of weld metal porosity when welding titanium alloys with Nd:YAG rod lasers have been developed. Characterisation of the welding processes using high speed photography and optical spectroscopy, have allowed an original scientific understanding of the effects these methods have on the keyhole, melt pool and vapour plume behaviour. Combining this with a thorough assessment of the weld qualities produced, has enabled the effects of these process behaviours on the formation of weld metal porosity to be determined. It was found that with the correct process parameters a directed gas jet and a dual focus laser welding condition can both be used to reduce the occurrence of keyhole collapse during Nd:YAG laser welding. The directed gas jet prevents the formation of a beam attenuating vapour plume and interacts with the molten metal to produce a stable welding condition, whereas the dual focus laser welding condition reduces fluctuations in the process due to an enlarged keyhole. When applied, both techniques reduced the occurrence of porosity in the weld metal of full penetration butt welds produced in titanium alloys. A modulated Nd:YAG laser output, with the correct waveform and modulation frequency, also reduced the occurrence of porosity in the weld metal compared with welds produced with a continuous-wave output. This was a result of an oscillating wave being set-up in the melt pool which manipulated the keyhole geometry and prevented instabilities in the process being established. In addition, the potential for welding titanium alloys to the required weld quality criteria with state-of-the-art Yb-fibre lasers has been assessed. It was found that the high power densities of suitably focussed laser beams with excellent beam quality, were capable of producing low-porosity full penetration butt welds in titanium alloys without the techniques required for laser beams with a lower beam quality. These new techniques for keyhole laser welding of titanium alloys will encourage the uptake of keyhole laser welding for producing near-net-shape high-performance aerospace components. The advantages offered by this joining technology include high productivity, low heat input and easy robotic automation.

WHY AM I GETTING POROSITY : r/Welding

Welding Defects - Classification, Causes and Remedies

Shielding Gas for Laser Welding: The Ultimate Guide - Baison

Understanding Fatigue Failure in Welded Structures

Welding Techniques

Dynamics of solid-liquid interface and porosity formation determined through x-ray phase-contrast in laser welding of pure Al - ScienceDirect

How Material Conditions Affect Welding Filler Metal Performance - Hobart Brothers

MMA Welding Quality: Understanding Common Problems - Welding & Welder

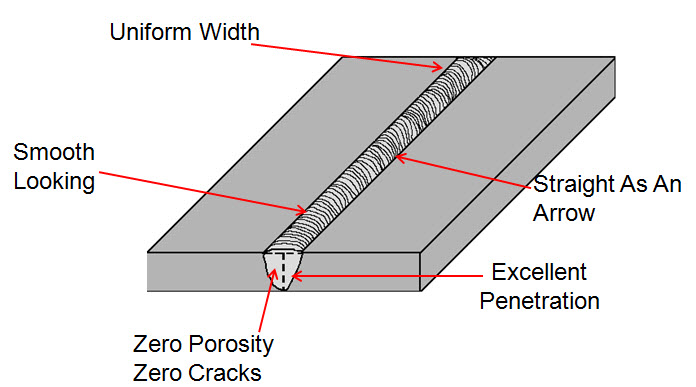

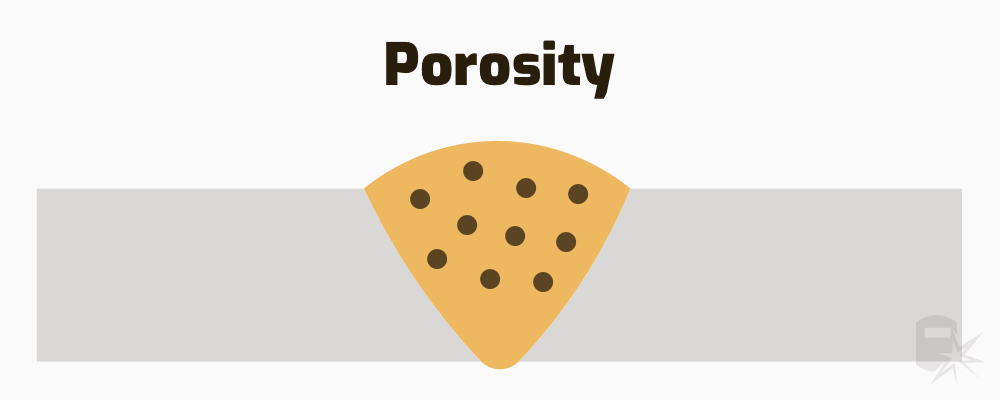

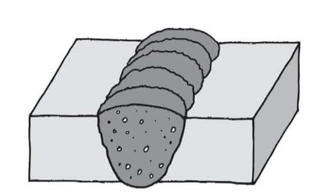

Porosity in Welding: What is it? And How to Prevent It

Challenges and solutions of reducing porosity formation during remote laser welding of die casting aluminium

What is Welding Porosity? Causes, Prevention & Fixes

What is the reason of porosity in welding? - Quora

Recomendado para você

-

SCP-10000, Wiki21 fevereiro 2025

SCP-10000, Wiki21 fevereiro 2025 -

SCP 10000 and 10000-02, Wiki21 fevereiro 2025

SCP 10000 and 10000-02, Wiki21 fevereiro 2025 -

SCP-2082 - SCP Foundation21 fevereiro 2025

SCP-2082 - SCP Foundation21 fevereiro 2025 -

Anker PowerCore Select 10000 2-Port Portable Charger Black21 fevereiro 2025

Anker PowerCore Select 10000 2-Port Portable Charger Black21 fevereiro 2025 -

Dawit Abebe, Artist21 fevereiro 2025

Dawit Abebe, Artist21 fevereiro 2025 -

_exploring-the-scp-foundation-scp-2951-10000-years-preview-hqdefault.jpg) Exploring the SCP Foundation: SCP-2951 - 10,000 Years from scp21 fevereiro 2025

Exploring the SCP Foundation: SCP-2951 - 10,000 Years from scp21 fevereiro 2025 -

Gigabyte UD1000GM PG5 & UD750GM 80+ Gold Power Supply Impressions21 fevereiro 2025

Gigabyte UD1000GM PG5 & UD750GM 80+ Gold Power Supply Impressions21 fevereiro 2025 -

PDF21 fevereiro 2025

PDF21 fevereiro 2025 -

Program Book - CSO at Wheaton: The Rite of Spring & Kavakos by Chicago Symphony Orchestra - Issuu21 fevereiro 2025

Program Book - CSO at Wheaton: The Rite of Spring & Kavakos by Chicago Symphony Orchestra - Issuu21 fevereiro 2025 -

D-4666/SCP-10000-2-A, Wiki21 fevereiro 2025

D-4666/SCP-10000-2-A, Wiki21 fevereiro 2025

você pode gostar

-

FINAL APOCALYPSE: O REQUIEM DAS SOMBRAS - 9786587068107 - Livros21 fevereiro 2025

FINAL APOCALYPSE: O REQUIEM DAS SOMBRAS - 9786587068107 - Livros21 fevereiro 2025 -

Ambatukam – Dreamybull Ambatukam Sheet music for French horn (Brass Quartet)21 fevereiro 2025

-

How would I make a Looking for Match thing like Bedwars? - Scripting Support - Developer Forum21 fevereiro 2025

How would I make a Looking for Match thing like Bedwars? - Scripting Support - Developer Forum21 fevereiro 2025 -

![MUGEN GAME] Double Dragon (NEO GEO) [ ダブルドラゴン ] by ZombieBrock, Vegaz & MUGEN PLAYER](https://i.ytimg.com/vi/VtkToyhRrDo/maxresdefault.jpg) MUGEN GAME] Double Dragon (NEO GEO) [ ダブルドラゴン ] by ZombieBrock, Vegaz & MUGEN PLAYER21 fevereiro 2025

MUGEN GAME] Double Dragon (NEO GEO) [ ダブルドラゴン ] by ZombieBrock, Vegaz & MUGEN PLAYER21 fevereiro 2025 -

King Cnut 2 Oz Viking Coin Series21 fevereiro 2025

King Cnut 2 Oz Viking Coin Series21 fevereiro 2025 -

/cdn.vox-cdn.com/uploads/chorus_image/image/72178596/1481941415.0.jpg) An analytical breakdown of Real Madrid's 2 - 0 win over Chelsea - Managing Madrid21 fevereiro 2025

An analytical breakdown of Real Madrid's 2 - 0 win over Chelsea - Managing Madrid21 fevereiro 2025 -

Light blue Little cow Roblox shirt, Roblox t shirts, Roblox21 fevereiro 2025

Light blue Little cow Roblox shirt, Roblox t shirts, Roblox21 fevereiro 2025 -

Ronald Araujo puede ver “ocho partidos por fin de semana21 fevereiro 2025

Ronald Araujo puede ver “ocho partidos por fin de semana21 fevereiro 2025 -

8 Ball Pool celebrates 10 year anniversary by releasing player metrics and special update21 fevereiro 2025

8 Ball Pool celebrates 10 year anniversary by releasing player metrics and special update21 fevereiro 2025 -

God of War: Ragnarok' Game Retailer Leaks Release Date from Sony Sta. Monica—When Is It Coming?21 fevereiro 2025

God of War: Ragnarok' Game Retailer Leaks Release Date from Sony Sta. Monica—When Is It Coming?21 fevereiro 2025